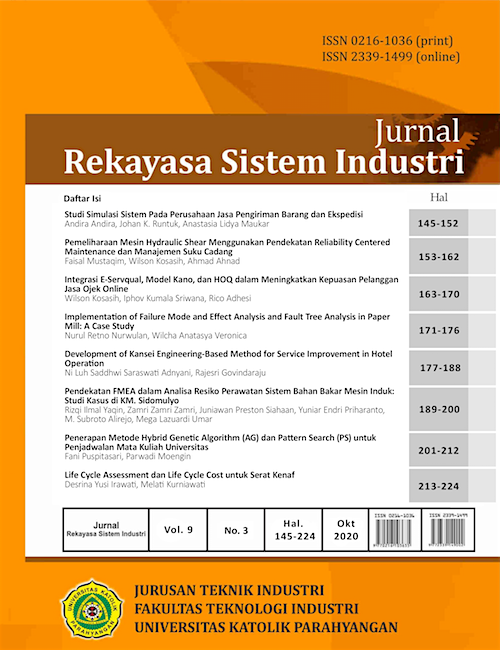

Pemeliharaan Mesin Hydraulic Shear Menggunakan Pendekatan Reliability Centered Maintenance dan Manajemen Suku Cadang

DOI:

https://doi.org/10.26593/jrsi.v9i3.4023.153-162Abstract

Production equipment that has a high operating time becomes a vital aspect in supporting the operational system, and its maintenance becomes a critical point that must be planned. This research discusses maintenance policies that focus on machine reliability and parts availability to produce proper maintenance actions, optimal maintenance scheduling and good spare-parts management. The research was conducted on a developing manufacturing company engaged the field of agricultural aids in the city of Bekasi. This study focused on hydraulic shear machines because they have the largest downtime value of 8,344.8 minutes. This problem has a negative impact on the company because it can reduce the yield. Based on these conditions, the study was conducted using the Reliability Centered Maintenance method to update the maintenance patterns and Poisson Process to determine the number of component requirements needed for the next one year. The data obtained in the form of historical damage to the machine, component cost, labor cost and production cost. This research produces an optimal preventive replacement time interval that is every 154 hours for the oil seal component, 242 hours for the shear blade component, and 324 hours for the oil hydraulic hose (1/2") component. While the number of critical components required for the next 1 year is 37 units for oil seal component, 10 units for shear blade components, and 7 units for oil hydraulic hose (1/2") component.References

Ahmad, Kosasih, W. & Wijoyo, B. (2014). Penentuan Jadwal Penggerindaan pada Mata Pahat Mesin Giling dan Penggantian Mata Gerinda dengan Menggunakan Metode Preventive Maintenance. Jurnal Kajian Teknologi, 10(2), 73-82.

Ahyari, A. (2002). Manajemen Produksi Perencanaan Sistem Produksi. Yogyakarta: BPFE UGM.

Anderson, T, W. & Darling, D, A. (1954). A Test of Goodnees of Fit. Journal of American Statistical Association, 49(268), 765-769.

Assauri, S. (1993). Manajemen Produksi dan Operasi. Jakarta: Lembaga Penerbit Fakultas Ekonomi UI.

Corder, A. (1996). Teknik Manajemen Pemeliharaan. Jakarta: Erlangga.

Dhillon, B.S. (2002). Engineering Maintenance: A Modern Approach. New York: CRC Press LLC.

Ebeling, C. (1997). An Introduction to Reliability and Maintainability Engineering. Singapore:The McGraw-Hill Company.

Indrajit, R., & Djokopranoto. (2003). Konsep Manajemen Supply Chain: Strategi Mengelola Manajemen Rantai Pasokan Bagi Perusahaan Modern di Indonesia. Jakarta: PT Gramedia Widiasaranan Indonesia.

Moubray, J. (1991). Reliability Centered Maintenance II, Second Edition. New York: Industrial Press Inc.

Jardine, A.K. (1993). Maintenance, replacement and reliability. Canada: Pittman Publishing Company.

Kennedy, J. (2009). What Is Maintenance?. The Asset Journal, 3(1), pp. 3-11.

Kosasih, W., Ahmad & Nurtanti, W. (2014). Pemeliharaan Terencana: Penjadwalan Interval Pembersihan Nozzle dan Penggantian Nozzle Heater pada Mesin Automatic Injection Molding E-110B (Studi Kasus: Perusahaan Guna Plast). Paper presented at 2nd Indonesian Statistical Analysis Conference, Bandung (pp. 211-214). Bandung, ID: Jurusan Teknik Industri Universitas Parahyangan.

Kurniawan, F. (2013). Manajemen Perawatan Industri Teknik dan Aplikasi. Yogyakarta: Graha Ilmu.

Render, B & Heizer, J. (2001). Prinsip-prinsip Manajemen Operasi. Jakarta: Salemba Empat.

Siddiqui, A. W. & Ben, M. (2009). Reliability Centered Maintenance in Handbook Of Maintenance Management and Engineering. London: Springer.

Stamatis, D.H. (1995). Failure Mode and Effect Analysis: FMEA from Theory to Execution. Milwaukee, WI: ASQC Press.