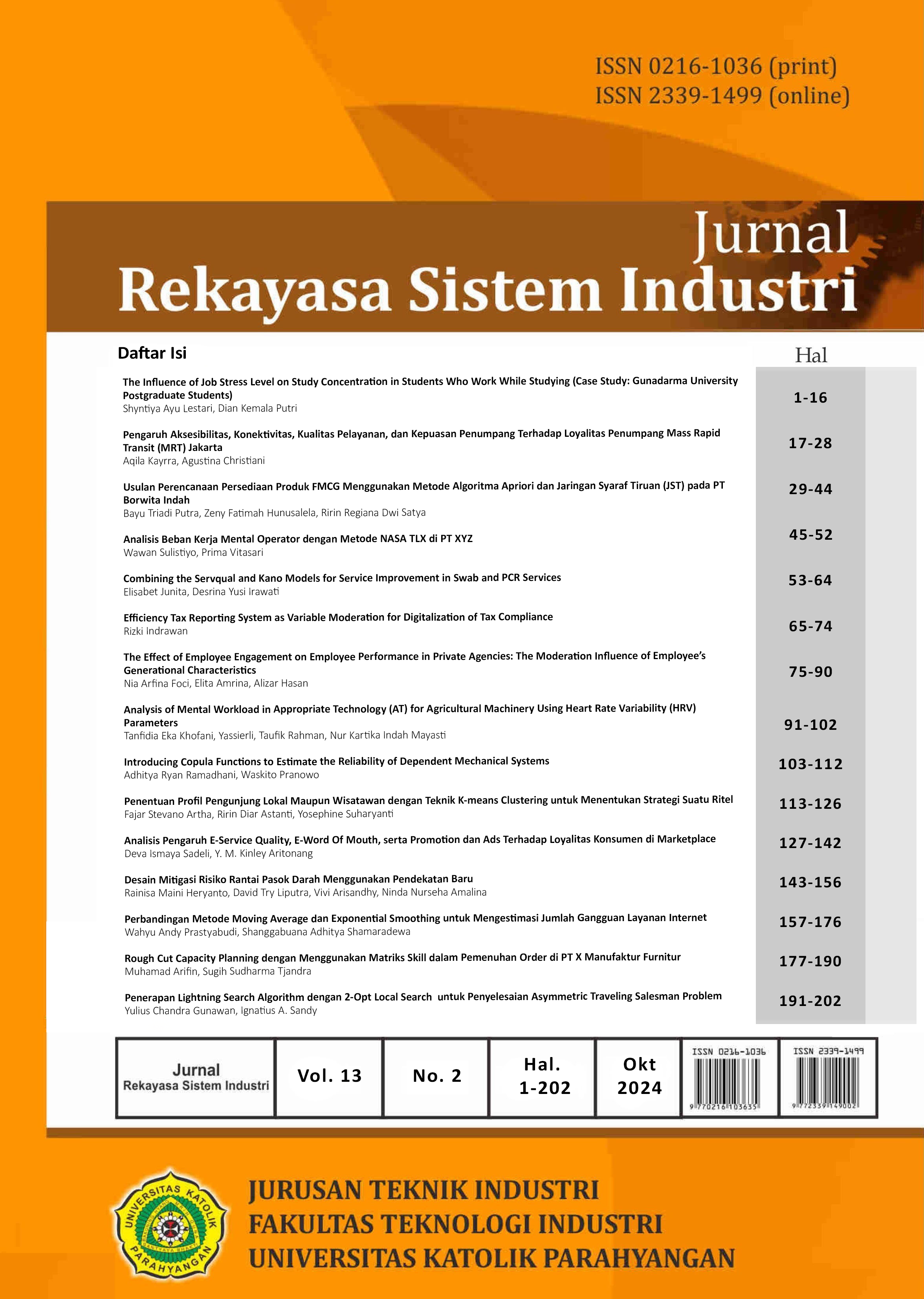

Usulan Perencanaan Persediaan Produk FMCG Menggunakan Metode Algoritma Apriori dan Jaringan Syaraf Tiruan (JST) pada PT Borwita Indah

Proposed FMCG Product Inventory Planning Using the Apriori Algorithm Method and Artificial Neural Network (ANN) at PT Borwita Indah

DOI:

https://doi.org/10.26593/jrsi.v13i2.7015.29-44Keywords:

Supply, Forecasting, Demand, Apriori, Artificial Neural NetworksAbstract

The problem faced by PT Borwita Indah is the occurrence of overstock and understock on FMCG products. This study aims to determine the inventory planning of FMCG products with related factors, namely sales results, stock of finished goods, and to be able to predict accurately so that there is no buildup of products in the warehouse. This research using the apriori algorithm for data collection with associative rules which is carried out through support and confidence calculation mechanisms and artificial neural networks for forecasting methods which have a fairly low data error rate and are good enough in the generalization process so that this model is able to predict timeseries data for several time periods for future. Itemset data pattern obtained resulted in a level of confidence in Head&Shoulders with Pantene 90.9%, and a level of confidence in Pantene with Head&Shoulders 90.9%. Meanwhile, the level of confidence for Vicks with Head&Shoulders reaches 100%. Forecasting results for the next 12 periods for each Pantene, Head&Shoulders, and Vicks product have a fluctuating forecasting trend so that safety stock can be taken into account. The amount of safety stock that must be in the company is 504 pcs of Pantene per day, 49 pcs of Head&Shoulders per day, 35 pcs of Vicks. It is hoped that with this research the company can carry out optimal product inventory control.

References

Amalia, T., Septiadi, M., Rafly, R., & Pranata, J. (2020). Analisis Perencanaan dan Pengendalian Produksi untuk Mengoptimumkan Biaya Produksi Ragum. Jurnal Talenta, 3(2), 265–272.

Badrul, M., Studi, P., & Informasi, S. (2016). Algoritma Asosiasi dengan Algoritma Apriori untuk Analisa Data Penjualan. Jurnal Pilar Nusa Mandiri, XII, 121–129.

Basuki. (2016). Optimasi Ukuran Pemesanan Lot Yang Ekonomis pada Permintaan Deterministik Dinamis Menggunakan Algoritma Wagner-Within. Industrial Engineering Journal, 5(1), 29–34.

Bilaffayza, E. S., Wahyudin, W., & Herwanto, D. (2023). Peramalan Permintaan Metode Moving Average dan Linier Regression dalam Memprediksi Produksi Produk Disc Brake K93 (Studi Kasus PT United Steel Center Indonesia). 10.

Indriyani, F., & Irfiani, E. (2019). Clustering Data Penjualan pada Toko Perlengkapan Outdoor Menggunakan Metode K-Means. JUITA : Jurnal Informatika, 7(2), 109.

Kurniawan, V. (2022). Analisis Persediaan Bahan Baku Pasir Besidi PT Semen Baturaja. Multidisipliner Kapalamada, 1(3), 406–411.

Kusrini & Luthfi, E. T. (2009). Algoritma Data Mining (T. A. Prabawati (ed.)). CV Andi Offset.

Mira Febrina, Faula Arina, R. E. (2013). Peramalan Jumlah Permintaan Produksi Menggunakan Jaringan Saraf Tiruan Algoritma Backpropagation. Jurnal Teknik Industri, 1(2), 174–179.

Nasution, A. H., & Prasetyawan, Y. (2008). Perencanaan dan Pengendalian Produksi. Graha Ilmu.

Rohana, B., Purba, B., & Ginting, G. L. (2018). Implementasi Algoritma Apriori untuk mencari Relasi pada Transaksi Pembelian Alat-Alat Kesehatan (Studi Kasus: RS. ESTOMIHI). 5.

Sri Kusumadewi. (2004). Membangun Jaringan Syaraf Tiruan Menggunakan MATLAB & EXCEL LINK. Yogyakarta: Graha Ilmu.

Thoriq, M. (2022). Peramalan Jumlah Permintaan Produksi Menggunakan Jaringan Saraf Tiruan Algoritma Backpropagation. Jurnal Informasi Dan Teknologi, 1(2), 27–32.

Windarto, Agus Perdana, D. (2020). Jaringan Saraf Tiruan: Algoritma Prediksi dan Implementasi (J. Simarmata (ed.); (Cetakan 1). Yayasan Kita Menulis.