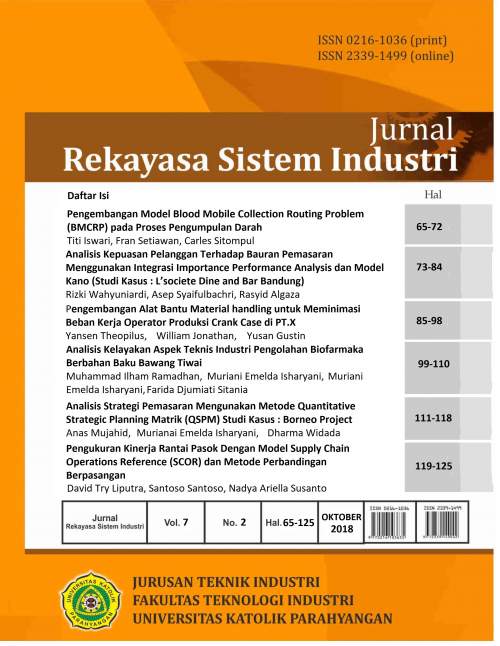

Pengembangan Alat Bantu Material handling untuk Meminimasi Beban Kerja Operator Produksi Crank Case di PT.X

DOI:

https://doi.org/10.26593/jrsi.v7i2.2832.85-98Abstract

This research aims to evaluate the workload of production operators at PT. X and develop a product/tools that can minimize the workload of production operators in PT.X factory. PT.X is a motorcycle manufacture company that produces sport bike, duck bike, and scooter bike along with its components. One of the main components produced in PT. X is crankcase. Crankcase function as a house for motorcycle machine components such as generator, oil pumps, clutches, crankshaft, transmission gear, and lubricating oil. This research focuses on crankcase production because the crankcase production operators have the most complaints regarding workload compared to others.

The research begins by evaluating the workload of the operators on the initial working system. The evaluation data is collected by some method such as direct field observation, direct measurement, and interview with the operators. After that, the data is processed to evaluate the mental and physical workload of the operators using NIOSH, RULA, and NASA-TLX methods. The Evaluation results show that there are several operators that have an excessive workload, especially for the material handling work. This activity results Lifting Index value of more than 1, a RULA value of more than 5, and a NASA-TLX value greater than 80.

Based on the evaluation, this research developed a material handling tool in the form of workpiece basket lifting equipment using a combination of pneumatic and hydraulic principles that can minimize the workload of the crankcase production operator at PT. X. This tool can eliminate a bending movement which is the source of problem in the operator's workload. The result of the evaluation of this tool application shows that the use of the tool can produce a reasonable workload for all crankcase production operators at PT. X.

References

Ansari, N.A. & Sheikh, M.J. (2014). Evaluation of work Posture by RULA and REBA: A Case Study. IOSR Journal of Mechanical and Civil Engineering, Vol. 11(4), 18-23.

Bappenas (2017). Perkembangan Ekonomi Indonesia dan Dunia triwulan 2017. Jakarta: Kedeputian Bidang Ekonomi Kamantrian PPN/Bappenas.

DiDomenico, A. & Nussbaum, M.A. (2011). Effects of different physical workload parameters on mental workload and performance. International Journal of Industrial Ergonomics, Vol. 41(3), 255-260.

Hart, S.G. & Staveland, L.E. (1988). NASA-TLX (Task Load Index). California: NASA Ames Research Center.

Hart, S.G. (2006). Nasa-Task Load Index (NASA-TLX); 20 Years Later. Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2006, Vol. 50, 904-908.

Jonathan, G.K. (2016). Maintaining Health and Safety at Workplace: Employee and Employer’s Role in Ensuring a Safe Working Environment, Journal of Education and Practice, Vol. 7(29), 1-7.

Knudson, D. (2007). Fundamentals of Biomechanics. Chico: Springer.

McAtamney, L. & Corlett, E.N. (1993). RULA: a survey method for the investigation of work-related upper limb disorders, Applied Ergonomics, Vol. 24(2), 91-99.

Middlesworth, M. (2007). A Step-by-Step Guide: Rapid Upper Limb Assessment (RULA). Ergonomics Plus, [Online], Diakses dari: http://ergo-plus.com/wp- content/uploa ds/RULA-A-Step-by-Step-Guide1.pdf [2018, 6 Februari).

Phinyomark, A., Quaine, F., & Laurillau, Y. (2014). The Relationship between Anthro-pometric Variables and Features of Electromyography Signal for Human-Computer Interface. Applications, Challenges, and Advancements in Electromyography Signal Processing, 321-353.

Ulrich, K. T., & Eppinger, S. D. (2012). Product Design and Development. New York: McGraw-Hill.

Stevenson, M. G. (1996). Principles of Ergonomics. Australia: Center for Safety Science-University of NSW.

Sutalaksana, I. Z., Anggawisastra, R., & Tjakraatmadja, J. H. (2006). Teknik Perancangan Sistem Kerja. Bandung: Departemen Teknik Industri ITB.

Trujillo, A.C. (2011). Evaluation of Electronic Formats of the NASA Task Load Index. Virginia: NASA Langley Research Center.

Umami, M. K., Hadi, A. D. R., & Agustina, F. (2014). Evaluasi Ergonomi Aktivitas Manual Material handling pada Bagian Produksi di CV. GMS, Bangkalan. Jurnal Rekayasa Sistem Industri, Vol. 3(2), 65-70.

Waters, T. R., Putz-Anderson, V. & Garg, A. (1994). Applications Manual For The Revised NIOSH Lifting Equation. Cincinnati Ohio: U.S Departement Of Health And Human Services.