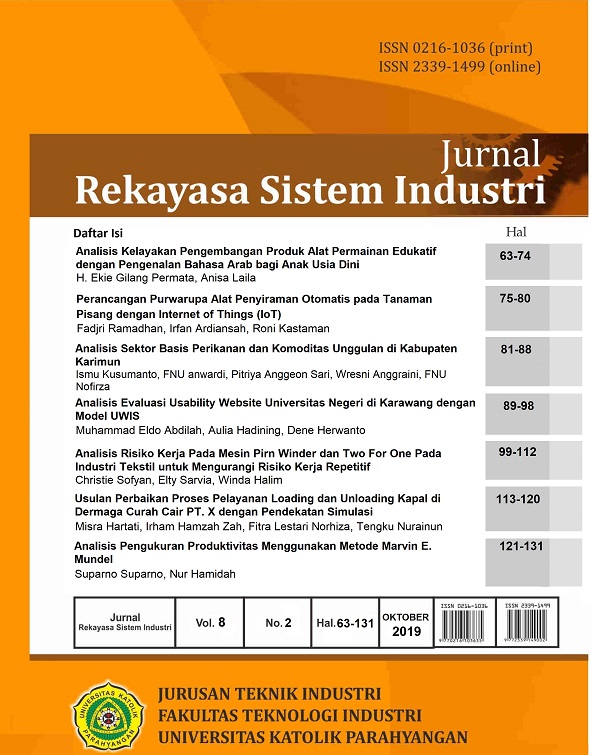

Analisis Risiko Kerja Pada Mesin Pirn Winder dan Two For One Pada Industri Tekstil untuk Mengurangi Risiko Kerja Repetitif

DOI:

https://doi.org/10.26593/jrsi.v8i2.3358.99-112Abstract

PT. X is a company engaged in the textile industry in Bandung. In one of the departments it owns, namely the weaving department, there are a number of machines to roll the yarn into sheets of cloth. Among these machines, there are 2 engines, namely Pirn Winder (PW) and Two For One (TFO) machines, which have almost the same function, which is rolling thread. In both machines, problems were found, namely operators working with a high workload, especially from repetition factors and poor work postures, so operators often complained of pain in their body parts. This is evident from the results of the preliminary research using the QEC method that the operator on the machine has an exposure level of more than 60% so that changes in the existing working conditions are needed. Using the method of Assessment Repetitive Task (ART) and REBA (Rapid Entire Body Assessment carried out measurement of repetitive working conditions that occur and also carried out measurements of the actual work posture. Then, the design of a tool in the form of a machine to reduce repetitions that occur must be done by the operator and improve operator work posture while working.The results were simulated using software and found out that the risk of repetition, posture has been reduced and there is a time savings of 67%.

References

Amelinda, B. S., & Iftadi, I. (2017). Hubungan Sikap Kerja dengan Keluhan Muskuloskeletal pada Pekerja Unit Weaving di PT Delta Merlin Dunia Textile IV Boyolali. Prosiding SNST Fakultas Teknik, 1(1).

Assesment Repetitive Task [Online], Diakses dari:http://www.hse.gov.uk/msd/uld/art/whatis.htm [Mei 2019]

Brown, R., & Li, G. (2003). The Development of Action Levels for the “Quick Exposure Check “(QEC) System. Contemporary Ergonomics, 1, pp. 41-46.

Colombini, D. (2002). Risk Assessment and Management of Repetitive Movements and Exertions of Upper Limbs: Job Analysis, Ocra Risk Indicies, Prevention Strategies and Design Principles (Vol. 2). Elsevier.

Evita, E.S (2017). Perbaikan Postur Kerja pada Operator Stasiun Two for One Bawah Menggunakan Metode REBA. Jurnal Sains, Teknologi dan Industri, Vol. 14, No.2, pp.199- 208.

Iridiastadi, H. & Yassierli. (2014). Ergonomi : Suatu Pengantar edisi pertama, PT Remaja Rosdakarya.

Nurmianto, E. (2004). Ergonomi : Konsep Dasar dan Aplikasinya edisi kedua. Surabaya: Guna Widya.

Stanton, N. A., Hedge, A., Brookhuis, K., Salas, E., & Hendrick, H. W. (Eds.). (2004). Handbook of human factors and ergonomics methods. CRC press.

Sutalaksana, I. Z., Anggawisastra, R., & Tjakraatmadja, J. H. (2006). Teknik perancangan sistem kerja. Bandung: ITB.

Tarwaka. (2010). Ergonomi Industri. Surakarta: Harapan Press.