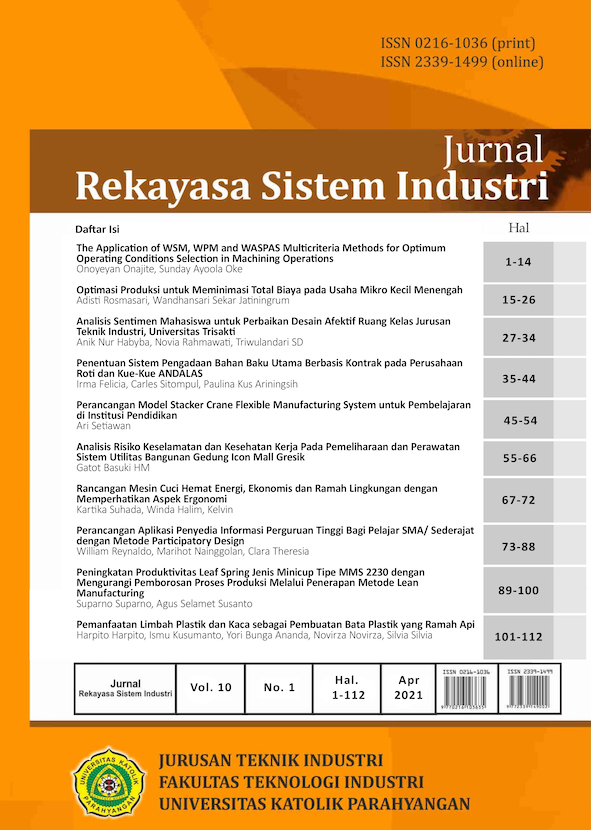

Peningkatan Produktivitas Leaf Spring Jenis Minicup Tipe MMS 2230 dengan Mengurangi Pemborosan Proses Produksi Melalui Penerapan Metode Lean Manufacturing

DOI:

https://doi.org/10.26593/jrsi.v10i1.3813.89-100Abstract

PT. Indospring is a manufacturing company that produces various springs for an automotive. Among those various springs, MSM 2230 type is the most produced spring at the company. The big problem in producing the spring was related with the high waste that had impact on the low productivity. The purpose of study was to analyze the waste by using the concept of lean manufacturing particularly to identify and eliminate nonvalue added activities. The study found that there were various wastes which waiting and excessive transportation were two dominant wastes with the contribution to total of wastes at 28.96% and 18.52% respectively. The appropriate tool for further analysis on wastes was selected by using value stream mapping analysis (VALSAT), and process activity mapping (PAM) was the best tool for analyzing wastes more profoundly. The use of PAM and other tools of fishbone diagram and failure mode effect analysis (FMEA) provided important information for improvement. The implementation of improvement displayed potential increase of productivity level by reducing the processing time of the spring from 113,926.83 minutes to 75,960 minutes

References

Adrianto, W., & Kholil, M. (2016). Analisis Penerapan Lean Production Process untuk Mengurangi Lead Time Proses Perawatan Engine (Studi Kasus PT.GMF AEROASIA). Jurnal Optimasi Sistem Industri, 14(2), 299-309.

Bhasin, S. (2013). Lean Management Beyond Manufacturing. Cham: Springer International Publishing.

Fernando, Y. C. (2014). Optimasi Lini Produksi dengan Value Stream Mapping dan Value Stream Analysis Tools, Jurnal Ilmiah Tekni Industri, 13(2), 125-133.

Gaiardelli, P. (2018). Faster, Better, Cheaper’ in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond. Production Planning and Control, 29(2), 184–184.

Hazmi, F. W., & Hakim, J. A. R. (2012). Penerapan Lean Manufacturing untuk Mereduksi Waste di PT. ARISU. Jurnal Teknik ITS, 1(1), 135-140.

Jakfar, A. & Setiawan, W. E. (2014). Pengurangan Waste Menggunakan Pendekatan Lean Manufacturing. Jurnal Ilmiah Tekni Industri, 13(1) , 43-53.

Khannan, M. S. A., & Haryono, H. (2017). Analisis Penerapan Lean Manufacturing untuk Menghilangkan Pemborosan di Lini Produksi PT. Adi Satria Abadi. Jurnal Rekayasa Sistem Industri, 4(1), 47-54.

Nuruddin, A. W., Setyanto, N. W., & Soenoko, R. (Tahun?). Implementasi Konsep Lean Manufacturing untuk Meminimalkan Waktu Keterlambatan Penyelesaian Produk ”A” sebagai Value Pelanggan: Studi Kasus Pt. Tsw (Tuban Steel Work),” Jurnal Rekayasa dan Manajemen Sistem Industri, 1 (1), 47-56.

Prayogo, T., & Octavia, T. (2013). Identifikasi Waste dengan Menggunakan Value Stream Mapping Di Gudang PT. XYZ. Jurnal Titra. 1(2), 119-126.

Rejeki, K. S., Sinulingga, S., & Tarigan, U. (2013). Evaluasi dan Analisis Produktivitas dengan Menggunakan Metode Marvin E. Mundel Di PT. XYZ, Jurnal Teknik Industri FT USU, 2(1), 48-53.

Ristyowati, T., & Muhsin, A. (2017). Minimasi Waste pada Aktivitas Proses Produksi dengan Konsep Lean Manufacturing. Jurnal Optimasi Sistem Industri, 10(1), 85-96.