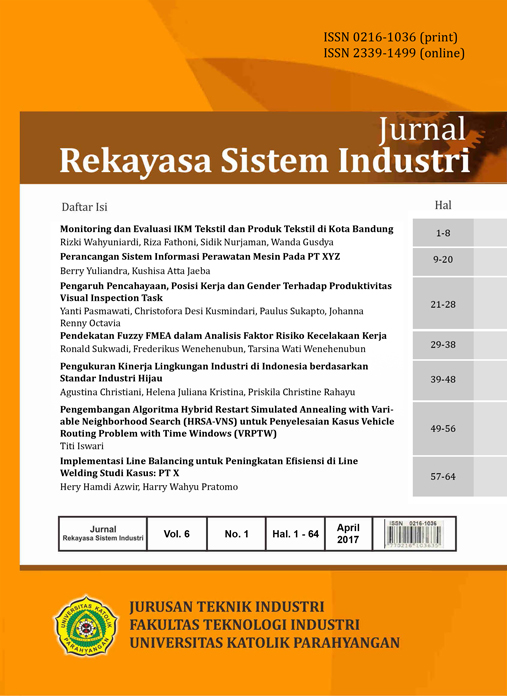

Perancangan Sistem Informasi Perawatan Mesin Pada PT XYZ

DOI:

https://doi.org/10.26593/jrsi.v6i1.2423.9-20Abstrak

Maintenance management is an important aspect that define success and sustainability of a manufacturing industry. The development of information technology give new possibilities to improve maintenance management performance. Data management with the help from information system will improve maintenance management effectiveness and efficiency. PT XYZ is an industry specialized in retreading tires service. Preliminary study on machinery maintenance process in PT XYZ showed that breakdown and maintenance data were not properly documented. This can generate high cost for the company because maintenance scheduling cannot optimally determined and the cost incurred by repair and maintenance activities, and also the cost of lost production time cannot determined directly. Therefore PT XYZ need information system to improve their maintenance management efficiency. Information system designed in accordance with company need based on system survey and interview. The design of information system developed using Object Oriented Analysis (OOA) and Object Oriented Design (OOD) approach. The designed information system can help maintenance management implementation and related data management. The availability of repair and maintenance data can help factory supervisor to make decision related to maintenance activities such as parts needed and maintenance cost.

Keywords: maintenance, information system, performance

Referensi

Arniaz, A., Emmanouilidis, C., Iung, B. dan Jantunen, E. (2006). Mobile Maintenance Management. Journal of International Technology and Information Management, Vol. 15 (4), 11-22.

Arts, R.H.P.M, Knapp, G.M. and Man, L. Jr. (1998). Some Aspects of Measuring Maintenance Performance in the Process Industry. Journal of Quality in Maintenance Engineering, Vol. 4 (1), 6-11.

Bartz, T., Siluk, J.C.M. dan Bartz, A.P.B. (2014). Improvement of Industrial Performance with TPM Implementation. Journal of Quality in Maintenance Engineering, Vol. 20 (1), 2-19.

Blaha, M. dan Rumbaugh, J. (2005). Object Oriented Modelling and Design with UML 2nd Edition, Prentice Hall.

Christer, A.H. dan Wang, W. (1995). A Simple Condition Monitoring Model for A Direct Monitoring Process. European Journal of Operational Research, Vol. 82 (2), 258-269.

Christianti, M. dan Wijaya, L. (2011) Aplikasi Pembelian, “Penjualan Obat dan Laporan Keuangan Dengan Menerapkan Manajemen Persediaan”, Jurnal Sistem Informasi, Vol. 6 (2).

Edi, D. dan Betshani, S. (2009). Analisis Data dengan Menggunakan ERD dan Model Konseptual Data Warehouse. Jurnal Informatika, Vol. 5 (1), 71-85.

Karim, R., Candell, O. dan Soderholm, P. (2009). E-Maintenance and Information Logistics: Aspects of Content Format. Journal of Quality in Maintenance Engineering, Vol. 15 (3), 308-324.

Kennedy, J. (2009). What Is Maintenance?, Journal The Asset, Vol. 3, Issue 1.

Khalil, J., Saad, S.M. dan Gindy, N. (2009). An Integrated Cost Optimization Maintenance Model for Industrial Equipment. Journal of Quality in Maintenance Engineering, Vol. 15 (1), 106-118.

Labib, A. W. (2008). Next Generation Maintenance Systems (NGMS): Emerging Educational and Training Needs to Support An Adaptive Approach to Maintenance Planning and Improve Decision Support. Proceedings of the 5th International Conference on Condition Monitoring and Machinery Failure Prevention Technologies, 15-18 Juli, Edinburgh, UK.

Leitch, R. A. dan Davis, K. R. (2005). Accounting Information Systems: Theory and Practice, Pennsylvania State University.

Meselhy, K.T., El Maraghy, W.H. dan El Maraghy, H.A. (2009). A Periodicity Metric for Assessing Maintenance Strategies. CIRP Journal of Manufacturing Science and Technology, Vol. 3 No. 2, pp. 135-141.

Mobley, R.K. (1989). An Introduction to Predictive Maintenance, New York: Butterworth-Heinemann.

Onohaebi, O. S. dan Lawal, Y. O. (2010). Poor Maintenance Culture: The Bane to Electrical Power Generation in Nigeria. Journal of Economics and Engineering, 28-33.

Organization for Economic Cooperation and Development (1963). Science and the Policies of Governments: The Implications of Science and Technology for National and International Affairs, Paris: OECD.

Parida, A. dan Kumar, U. (2006). Maintenance Performance Measurement (MPM): Issues and Challenges. Journal of Quality in Maintenance Engineering, Vol. 12 (3), 239-251.

Prihatini, P. M. (2012). Kajian Prosedur dan Model Sistem Penerimaan Mahasiswa Baru Online Politeknik Negeri Bali. Jurnal Logic, Vol. 12 (1), 38-45.

Raheja, D., Llinas, J., Nagi, R. dan Romanowski, C. (2006). Data Fusion/ Data Mining-Based Architecture for Condition-Based Maintenance. International Journal of Production Research, Vol. 44 (14), 2869-2887.

Samat, H. A., Kamaruddin, S. dan Azid, I. A. (2011). Maintenance Performance Measurement: A Review. Pertanika Journal Science and Technology, Vol. 19 (2), 199-211.

Sachdeva, A., Kumar, D. dan Kumar, P. (2008). Planning and Optimizing the Maintenance of Paper Production Systems In A Paper Plant. Computers & Industrial Engineering, Vol. 55 (4), 817-829.

Tretten, P. dan Karim, R. (2014). Enhancing the Usability of Maintenance Data Management Systems. Journal of Quality in Maintenance Engineering, Vol. 20 (3), 290-303.

Verron, S., Li, J. dan Tiplica, T. (2010). Fault Detection and Isolation of Faults In A Multivariate Process With Bayesian Network. Journal of Process Control, Vol. 20 (8), 902-911.

Wang, W. (2000). A Model to Determine the Optimal Critical Level and the Monitoring Intervals in Condition Based Maintenance. International Journal of Production Research, Vol. 38 (6), 1425-1436.

Yuliandra, B. (2011). Hierarchical Maintenance Performance Measurement: A Literature Study, Proceeding of 2nd International Forum on Facilities and Asset Management (IFFAM), 21 November, Padang, Indonesia, 85-93.