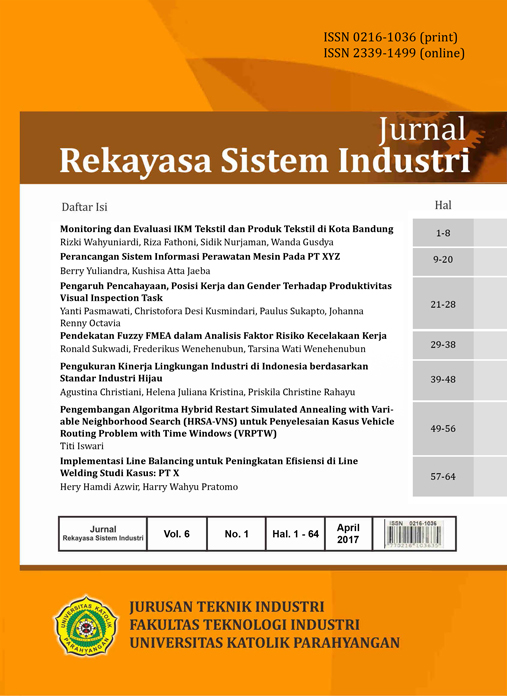

PENGARUH PENCAHAYAAN, POSISI KERJA DAN GENDER TERHADAP PRODUKTIVITAS VISUAL INSPECTION TASK

DOI:

https://doi.org/10.26593/jrsi.v6i1.2424.21-28Abstrak

Visual inspection task is the inspection activity of a product with the eye position centered over the moving conveyor, the faster the product is produced, the more critical the time of the inspection operator. The conditions in the long term will result in a decrease in productivity (Manuaba, 1992). The research objective to be achieved, among others: (1) Determining the optimal level of productivity based on the studies measure of performance checks on experimental design in every visual inspection task beverage packaging cup "Panther". (2) Determine the influence of lighting, working position and gender on the productivity of visual inspection task on beverage packaging. The object of research is part operator checks on beverage packaging cup "panther". Here are 10 people who have IQ scores of 90-120 aged 20-25 years. The research method was experimental method. The independent variables consist of lighting levels, working position, and gender. Variable manipulated into 12 groups experimental design. Data processing is done by checking the performance measurement approach. Analysis of experimental data using Analysis of Variance (ANOVA), and productivity. The study states that: (1) the highest labor productivity LkB200 experimental design (male, standing working position, the lighting level of 200 Lux) for 0.833. But the productivity of all design experiments have not reached optimal productivity, (2) Areas of different interactions in experimental design factor is the level of lighting in the working position. These factors affect the number of detected defects and work productivity.

Keywords: Lighting, Measurement Time, Productivity, Performance Measures Inspection, Analysis of Variance (ANOVA)

Referensi

Azwar, S.(2006). Pengantar Psikologi Inteligensi. Yogyakarta: Pustaka Pelajar.

Chengalur, N.S., et al.(2004). Kodak’s Ergonomic Design For People At Work, (2th ed.).The Eastman Kodak company. Amerika.

Dunn, N. & Wiliamson, A.(2012). Driving Monotonous Routes in a Train Simulator. The Effect of Task Demand on Driving Performance and Subjective Experience. Ergonomic, Vol.55 (9), pp. 997-1008.

Manuaba, A.(1992). Pengaruh Ergonomi Terhadap Produktivitas. Dalam Seminar Produktivitas Tenaga Kerja, Jakarta.

Pasmawati,Y., Rachmawati.(2013). Pengaruh Desain Lingkungan Fisik Dalam Ruangan Terhadap Produktivitas Berpikir (kognisi). Prodising Seminar Nasional Teknik Industri (SNTI), ISSN. 2338-7122, pp. 54-61.

Poulton, E.C.(1973). The effect of fatigue inspection work. Applied Ergonomics, pp. 73-83. Department of Engineering Production,University of Birmingham. Birmingham.

Sutalaksana Z, Iftikar., Dkk.(2006). Teknik Perancangan Sistem Kerja, (Edisi kedua). ITB: Bandung.

Tarwaka.(2014). Ergonomi industri. Solo: Harapan Press.

Tarwaka.(2014). Ergonomi Industri: Dasar-Dasar Pengetahuan Ergonomi dan Aplikasi Di Tempat Kerja. Surakarta: Harapan Press Surakarta.

WHO. (2009). Global status report on road safety. World Health Organisation:Geneva.

WHO. (2010). Equity, Social Determinants and Public Health Programs. World Health Organisation: Geneva.