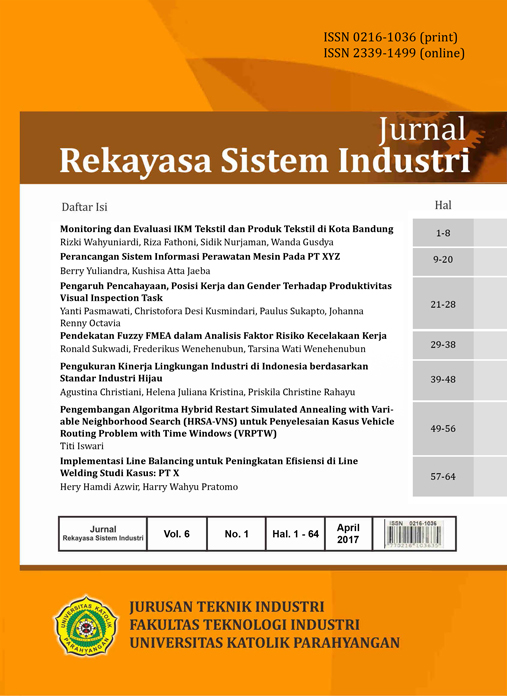

Implementasi Line Balancing untuk Peningkatan Efisiensi di Line Welding Studi Kasus: PT X

DOI:

https://doi.org/10.26593/jrsi.v6i1.2428.57-64Abstrak

Line balancing is a jobs assignment into a number of work stations that are interrelated in a track or a production line with an objective to minimizing the idle time on the line that is determined by the slowest operation. In line welding 1DY models includes eight work stations where one work station is done by one operator. Problems have been found that these operators have very long idle time and also there is too much wip that creates bottleneck in the production line so these leads to a waste of manpower and time. This waste of manpower and time need to be reduced by determining the optimal amount of labor in order to avoid excessive idle time but work can be done effectively and efficiently. One way to adress imbalance line is to apply line balancing methods.The results of this research shows that the line balancing methods can reduced the waste of time and give solutions for the optimal amount of labor requirements for line welding 1DY models.

Keywords: Line Balancing, Workstation, Production Line, Idle Time, Bottleneck.

Referensi

Boysen, N., Malte Fliedner, dan Armin School. “A Classification of Assembly Line Balancing Problems”. Europan Journal of Operation Research, 2007: 183.

Elsayed, E. A., dan Boucher, T.O. (1994). Analysis and Control of Production Systems. 2nd Edition. Englewood Cliffs, New Jersey: Prentice Hall International, Inc.

Purnomo, H. (2004). Pengantar Teknik Industri. Edisi Kedua. Yogyakarta: Graha Ilmu.

Wignjosoebroto, S. (2003). Teknik Tata Cara dan Pengukuran Kerja, Edisi ketiga Guna Widya, Surabaya.