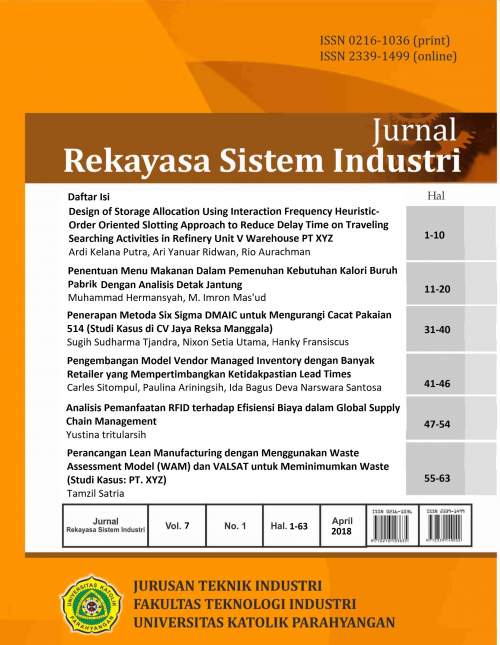

Pengembangan Model Vendor Managed Inventory dengan Banyak Retailer yang Mempertimbangkan Ketidakpastian Lead Times

DOI:

https://doi.org/10.26593/jrsi.v7i1.2770.41-46Abstrak

An inventory management system in supply chains called Vendor Managed Inventory (VMI) is very promising due to the cost efficiency resulted from implementing such system. This research aims to develop a vendor managed inventory for multiple retailers. The model also takes into account lead time uncertainties from vendor to its retailers. A mathematical formulation for VMI with multiple retailers is first developed using deterministic lead times. Subsequently, lead times uncertainties are then taken into account where modes lead times are broken into two components: modes and delays, each with their respective probabilities. In turn, an approximation model is used to solve the problem because the complexity aroused from the model is difficult to solve using analytical methods. It is shown that the proposed approximation method is able to solve VMI problem with multiple retailers and uncertain lead times. Furthermore, the total inventory cost is significantly reduced when compared to the usual economic order quantity method because stockouts are less frequent.

Referensi

Ariningsih, P.K, Shopa, B.M, and Subagyo (2007). Analisis pengaruh vendor managed inventory pada performansi supply chain, Jurnal Mesin Industri 4 (1), pp 1-14

Christiansen, P.E. (t.t) Vendor-managed Logistic from a Purchasing Perspective, Supply Chain Management, pp. 88 – 91, http://www.touchbriefings.com/pdf/967/christiansen.pdf, tanggal akses: 13 Maret 2006

Dong, Y. and Xu, K. (2002). A supply chain model of vendor managed inventory, Transportation Research Part E 38, pp 75-95.

Graves, S.C., and Willems, S.P. (2000). Optimizing strategic safety stock placement in supply chains, Manufacturing and Service Operations Management 2(1), 68-83.

Hong, X., Chunyuan, W., Xu, L., and Diabat, A., (2016). Multiple-vendor multiple-retailer based vendor managed inventory. Annals of Operations Research, 238, 277-297.

Mulvey, J. M., and Vanderbei. R. J. (1995). Robust optimization of large-scale system. Operation Research, Vol. 43, 264-281.

Rostenila, A., and Sitompul C., (2016). A robust optimization model for lot sizing with dynamic demands. Proceedings Asia Pacific Industrial Engineering and Management Society (APIEMS), Taipei.

Simchi-Levi, D., and Simchi-Levi, E. (2010) Designing and Managing Supply Chain 3rd edition, Mc. Graw-Hill, New York

Singh, R.K (2013) Analyzing the Factors for VMI Implementation: A Framework, Global Business Review 14 (1), pp 169-186

Sitompul, C. and Alfian (2012) Pengembangan Model Persediaan yang Dikelola Pemasok (Vendors Managed Inventory), Lembaga Penelitian dan Pengabdian kepada Masyarakat, Universitas Katolik Parahyangan, Bandung.

Sterman, J.D (2000) Business Dynamics: System Thinking and Modelling, Mc. Graw-Hill, New York

Tersine, R.J (1994) Principle of Inventory and Material Management, 4th edition, New Jersey: Prentice Hall

Yao, Y., Evers, P.T., and Dresner, M.E. (2005). Supply chain integration in vendor-managed inventory, Decision Support Systems 43, pp. 663-674.