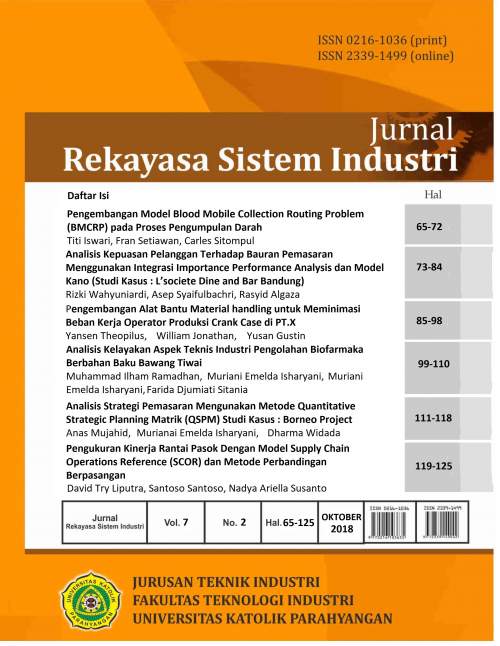

Analisis Kelayakan Aspek Teknis Industri Pengolahan Biofarmaka Berbahan Baku Bawang Tiwai

DOI:

https://doi.org/10.26593/jrsi.v7i2.2974.99-110Abstrak

From Latin Eleutherina American L. Merr, tiwai onion is one of species of flowering and bulbous plants in Borneo forest that can be developed as biopharmaceutical source for industrial scale. Tiwai onion beverage product is a product that has the benefits of tiwai onion plant in the tea bag form. Industrial development of tiwai onion processing into a tea bag product in UKM Solaindo still has many technical constraints. Therefore, it is necessary to conduct a research which aims to design technical aspect to ensure a smooth production process of tiwai onion tea. This research is expected to overcome the technical constraints faced by UKM Solaindo, so that tiwai onion product into a tea bag product in UKM Solaindo could get bigger and get increased to fulfill the market needs and also to become a competitive local product. Technical aspects examined include determining a factory location, production capacity, machinery and equipment, and factory facility layout. Determining a factory location using qualitative method (ranking procedure) determined that Tenggarong is the best location to establish an industrial factory of tiwai onion with the total score of 15.90. Production capacity is conducted by demand forecasting using weighted moving average method, and forecasting value obtained is 618 units/month or 66,74 Kg/month. Machinery and equipment used for production process from the factory that will be set up in every process are tray, automatic sealer machine, washing machine, oven, chopping machine, stamping equipment, and sealer machine. The most appropriate scoring systems for factory facility layout are ARC, ARD, SRD, and AAD that have 10 facilities such as administration room facilities with area of 80 m2, production facilities 37,5 m2, shipping facilities 7,5 m2, material warehouse facilities 15 m2, finished product warehouse facilities 17,5 m2, reception facilities 7,5 m2, quality control facilities 12 m2, power plants facilities 6 m2, waste shelter facilities 4 m2, and parking facilities 60 m2.

Key-words: Factory layout, machine, production capacity, ranking Procedure, tiwai onions

Referensi

Abdisobar, R., Bakar, A., Yuniar. 2014. Analisis Kelayakan Usaha Budidaya Jamur Tiram di Desa Cilame Ciwidey Kabupaten Bandung, Jurnal Online Institut Teknologi Nasional, vol. 02, no. 01, hh. 169-179.

Azis, J.A., 2008, Analisis Prospek Pengembangan Industri Sirup Salak Bangkalan, Embryo Vol. 5 No.1.

Azizah, F.A., Wijana, S., dan Effendi, M., 2014. Analisis Kelayakan Teknis dan Finansial pada Industri Pengolahan Karet Skala Kecil di Kabupaten Musi Rawas Sumatera Selatan. Malang: Universitas Brawijaya.

Fahmi, I., 2014, Manajemen Produksi dan Operasi, Bandung: Alfabeta.

Hadiguna, R.A., dan Setiawan, H., 2008, Tata Letak Pabrik, Yogyakarta: Andi Offset.

Indrajit, R.E., dan Permono, A., 2005. Manajemen Manufaktur Tinjauan Praktis Membangun dan Mengelola Industri. Yogyakarta: Pustaka Fahima.

Kasmir, dan Jakfar., 2012, Studi Kelayakan Bisnis Edisi Revisi, Jakarta: Kencana.

Kusuma, H., 2009, Manajemen Produksi Perencanaan dan Pengendalian Produksi, Yogyakarta: Andi.

Mentri Perindustrian-RI, 2016, Peraturan Mentri Perindustrian Republik Indonesia nomor 40/M-IND/PER/6/2016 Tentang Pedoman Teknis Pembangunan Kawasan Industri.

Naganingrum, R.P., Jauhari, W.A., & Herdiman, L., 2013. Perancangan Ulang Tata Letak Fasilitas di PT Komala dengan Metode Systematic Layout Planning, Performa, vol. 12, no. 1, hh. 39-50.

Neufert, E., 2002, Data Arsitek Edisi 33 Jilid 2, Jakarta: Erlangga.

Prasetya, A.T., Nugraha, C., Arijanto, S., 2014. Analisis Kelayakan Bisnis Kertas Berbahan Baku Rumput Laut Sebagai Alternatif Bahan Baku pada Industri Kertas. Jurnal Online Institut Teknologi Nasional, vol. 01, no. 03, hh. 139-151.

Pridianto, R.W., Effendi, U., dan Mulyadi, A.F., 2014. Analisis Kelayakan Teknis dan Finansial Produksi Selai dari Tanaman Nipah. Malang: Universitas Brawijaya.

Profita, A., Utomo, D.S., Burhandenny, A.E., Lois, A.J., 2016. Perancangan Aspek Teknis dan Produksi pada Industri Pengolahan Rumput Laut Menjadi Produk Nata De Seaweed, Seminar Nasional Ienaco Universitas Negeri Surakarta, ISSN: 2337-4349.

Sugiyono., 2013, Metode Penelitian Kuantitatif, Kualitatif, dan R&D. Bandung: Alfabeta.

Wignjosoebroto, S., 2009, Tata Letak Pabrik dan Pemindahan Bahan Edisi Ketiga Cetakan Keempat. Surabaya: Guna Widya.