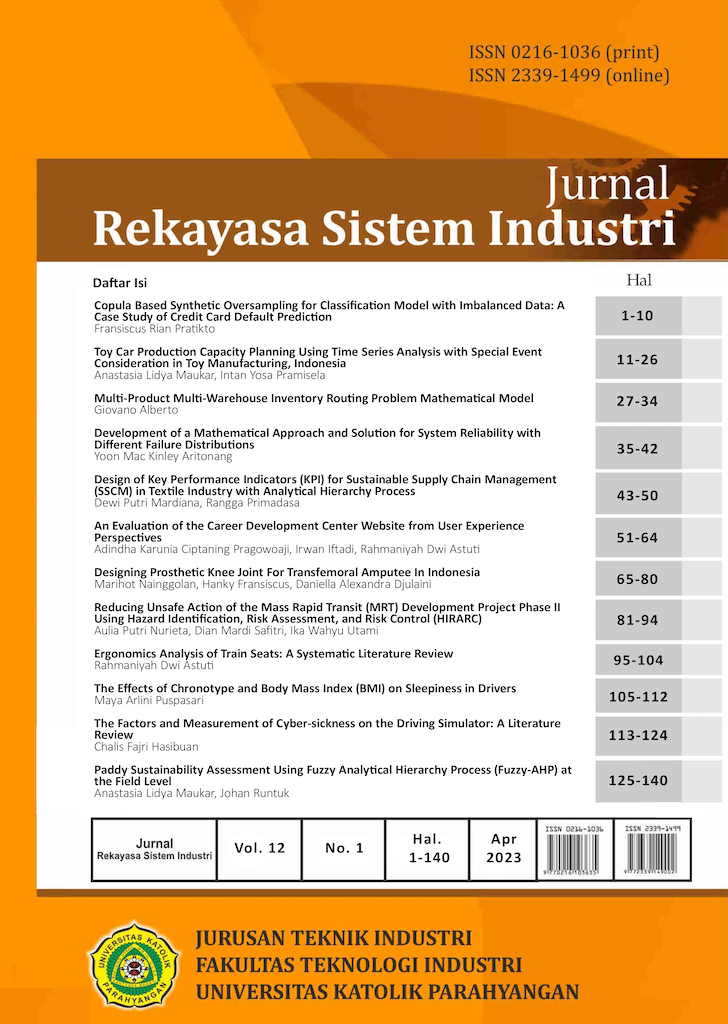

Perencanaan Kapasitas Produksi pada Produk Mobil Mainan Menggunakan Analisis Time Series dengan Mempertimbangkan Special Event pada Toy Manufacturing, Indonesia

DOI:

https://doi.org/10.26593/jrsi.v12i1.5752.11-26Kata Kunci:

perencanaan kapasitas, peramalan, special events, metode transportasi, excel VBA macroAbstrak

Toy Manufacturing Indonesia adalah perusahaan mainan multinasional dari Amerika Serikat. Salah satu product yang di hasilkan adalah FashionD dan HotW. Perencanaan kapasitas merupakan salah satu bagian dari perencanaan dan pengendalian produksi, merupakan upaya efisiensi untuk meningkatkan pemanfaatan sumber daya perusahaan. Periode 2021 Permintaan mobil mainan saat Special Event seperti Thanksgiving, Black Friday, Natal, dan Malam Tahun Baru terjadi secara berkala atau musiman dan setiap tahun menunjukkan pola tren positif. Toy Manufacturing Indonesia pada musim puncak permintaan Natal, terjadi lost sale sebanyak 844 ribu mobil. Lost sales terjadi karena permintaan telah melebihi kapasitas yang tersedia pada waktu reguler dan lembur. Sebaliknya, pada periode tidak ada lonjakan permintaan (non-special event), masih ada kapasitas yang dapat digunakan. Hal ini terlihat dari utilisasi kapasitas waktu reguler pada periode non special event, yaitu 82% di bawah rata-rata per tahun. Penelitian ini menunjukkan bahwa peningkatan akurasi peramalan, metode transportasi perencanaan agregat dapat meningkatkan pemanfaatan kapasitas waktu reguler di acara non-khusus hingga 90%, dan semua permintaan dapat dipenuhi (tidak ada penjualan yang hilang) dan program perancangan sistem yang diusulkan menggunakan excel VBA macro yang dapat melaksanakan produksi dengan kapasitas tinggi secara efisien dan efektif.

Referensi

Elinta, S. (2019). Forecast Seasoning Product at PT . Sa Using Time Series Method and Neural. Skripsi Studi Teknik Industri President University.

Irawan, Nasiatin, T., Adha, S., Juliyanto, O., Rani, C.P., & Dimas R, P. K. (2020). Analysis of Production Capacity Planning and Control in PT . Krakatau Wajatama With Rought Cut Capacity Planning ( RCCP ). Journal Industrial Engineering & Management Research 1(2), 207–218. doi: doi.org/10.7777/jiemar.v1i2.61.

Juliantara, I. K, & Mandala, K. (2020). Planning and Control of Aggregate Production at Tedung Ud Dwi Putri Business in Klungkung. E-Jurnal Manajemen Universitas Udayana 9(1), 99-118. doi: 10.24843/ejmunud.2020.v09.i01.p06.

Makridakis, S. G., Wheelwright, S,C., & Hyndman, R.J.. (1998). Forecasting: Methods and Applications, (3rd ed,). New York: Wiley.

Martha, K. A. & Setiawan, P.Y. (2018). Analisis Material Requirement Planning Product Coconut Sugar Pada Kul-Kul Farm. E-Jurnal Manajemen Universitas Udayana 7(12), 6532-6560. doi: 10.24843/ejmunud.2018.v07.i12.p06.

Maukar, A.L, , Andira, Runtuk, J.K. & Mashudi. (2019). Peramalan Tepung Jeli dengan Time Series Analysis Mempertimbangkan Pengaruh Special Event. Prosiding Seminar Nasional Cendekiawan ke 5 Tahun 2019, 1.26.1–7. doi:org/10.25105/semnas.v0i0.5696,

Mehrmolaei, S., & Keyvanpour, M.R., (2016). “Time Series Forecasting Using Improved ARIMA.” Artificial Intelligence and Robotics, IRANOPEN 2016 92–97. doi: 10.1109/RIOS.2016.7529496.

Nilolopoulus, K. (2010). Forecasting with Quantitative Methods: The Impact of Special Events in Time Series. Applied Economics 42(8), 947-955. https://doi.org/10.1080/00036840701721042.

Paul, S. K,, Sarker, R, & Essam, D. (2014). Managing Real-Time Demand Fluctuation under a Supplier-Retailer Coordinated System. International Journal of Production Economics 158:231–43. doi: 10.1016/j.ijpe.2014.08.007.

Pujawan, I.N. (2019). Logistics and Supply Chain Management. International Journal of Psychosocial Rehabilitation 23(6):361–66. doi: 10.37200/IJPR/V23I6/PR190779.

Putra, I.N., Pujawan, I.N., & Arvitrida, N.I. (2011). Peramalan Permintaan Dan Perencanaan Produksi Dengan Mempertimbangkan Special Event di PT. Coca-Cola Bottling Indonesia (PT. CCBI) Plant-Pandaan. Jurnal Teknik Industri 1–13.

Rathfelder, C., Kounev, S. & Evans, D. (2011). Capacity Planning for Event-Based Systems Using Automated Performance Predictions. 26th IEEE/ACM International Conference on Automated Software Engineering, ASE 2011, Proceedings 352–61. doi: 10.1109/ASE.2011.6100073.

Sultana, M.N., Shohan, S., & Sufian, F. (2014). Aggregate Planning Using Transportation Method: A Case Study In Cable Industry. International Journal of Managing Value and Supply Chains 5(3),19–35. doi: 10.5121/ijmvsc.2014.5302.

Takey, F.M. (2006). Aggregate Planning for a Large Food Manufacturer with High Seasonal Demand Brazilian Journal of Operations & Production Management 3(1), 5–20.

Walfried, Y. (2021). Metode Exponential Smoothing Event Based. Skripsi Studi S1 Matematika Universitas Sumatera Utara .

Widjajati, F.A. (2017). Menentukan Penjualan Produk Terbaik di Perusahaan X Dengan Metode Winter Eksponensial Smoothing Dan Metode Event Based. Limits: Journal of Mathematics and Its Applications 14(1), 25-35. doi: 10.12962/limits.v14i1.2127.