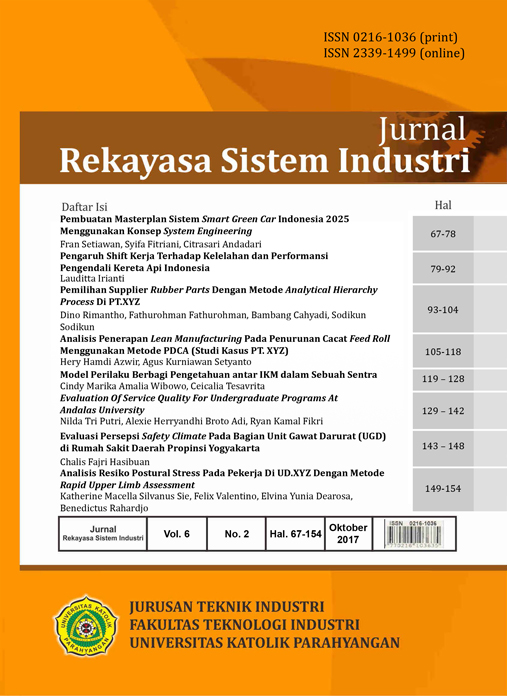

Analisis Penerapan Lean Manufacturing Pada Penurunan Cacat Feed Roll Menggunakan Metode PDCA (Studi Kasus PT. XYZ)

DOI:

https://doi.org/10.26593/jrsi.v6i2.2714.105-118Abstrak

PT XYZ is a company that produce tools, machine parts, and special purpose machines. Based on data from the production department, there are some products with high defect and then need rework. This condition would be very harmful because it will increase the cost that should not be necessary. The research is to find the cause of the occurrence of this defect and then fix it. From the observation result showed that the production of feed roll component has a high defect rate which is 70.59% must be reworked, based on the data during January - September 2016. In October - December 2016 the improvement effort was done by using lean manufacturing approach and PDCA. The results of this improvement provide improved quality of the feed roll component so that the rework gradually decreases and eventually does not exist. Then the cost of production before the repair of Rp 668,694, - reduced to Rp 413,983, -. There was a significant decrease in production cost by 38%.

Referensi

Abadi, Satria. “Analisis Penerapan Lean Manufacturing Untuk Menghilangkan Pemborosan Di Lini Produksi PT Adi.” Jurnal Rekayasa Sistem Industri Vol 4, No. 1 (2015): 47–54.

Adrianto, Wahyu, dan Muhammad Kholil. “Analisis Penerapan Lean Production Process Untuk Mengurangi Lead Time Process Perawatan Engine (Studi Kasus PT. GMF Aeroasia).” Jurnal Optimasi Sistem Industri Vol. 14, No. 2 (2016): 299–309.

Asefeso, A. (2007). Lean Implementation: (Why Lean Fails and how to Prevent Failure). Swindon: AA Global Sourcing Ltd.

Asefeso, A. (2011). 5s Lean Manufacturing: (Key to Improving Net Profit). Swindon: AA Global Sourcing Ltd.

Dennis, P. (2016). Lean Production Simplified, Third Edition: A Plain-Language Guide to the World's Most Powerful Production System. Florida: CRC Press.

Hines, P., & Taylor, D. (2000). Going Lean. Cardiff: Lean Enterprise Research Centre, Cardiff Business School.

Indra, Rudy, dan Zulfa Fitri. “Perbaikan Sistem Produksi Minyak Angin Aromatherapy Melalui Lean Manufacturing Di PT. US, Jawa Barat.” J@TI Undip: Jurnal Teknik Industri Vol. 8, No. 2 (2013): 99–106.

Liker, J. K. (2003). The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer. New York: McGraw Hill Professional.

Morfaw, J. N. (2009). Total Quality Management (TQM): A Model for the Sustainability Of Projects And Programs In Africa. Lanham: University Press Of America.

Setiawan, Wahyu Eko, And Ilyas Masudin. “Reducing Waste Dengan Menggunakan Pendekatan Lean Manufacturing.” Spektrum Industri Vol. 13, No. 1 (2015): 43–53.

Utama, Dana Marsetiya, Shanty Kusuma Dewi, And Veronika Indah Mawarti. “Identifikasi Waste Pada Proses Produksi Key Set Clarinet Dengan Pendekatan Lean Manufacturing.” Jurnal Ilmiah Teknik Industri Vol. 15, No. 1 (2016): 36–46